What is Weathering Steel? - Its Benefits, Grades & Chemical Composition

by AMC

Posted on January 19, 2023 at 12:52 PM

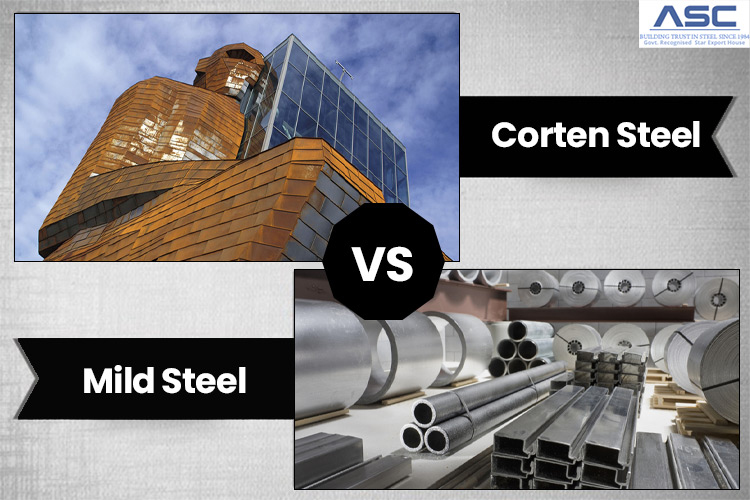

What is Meant by Weathering Steel?

Weathering steel is a family of low-carbon steels that have other elements mixed in with the carbon and iron. Because of these alloying elements, weathering steel is stronger and less likely to rust than most low-carbon steel grades. Because of this, weathering steel is often used outside or in other places where regular steel would be likely to rust.

Benefits of Weathering Steels:

Wide Range of Uses: Because weather-resistant steel doesn't rust in the air, it can

be used without paint in many structural and architectural applications, such as bridges, open-frame

buildings, transmission towers, and sculptures. Weathering steel can also handle high temperatures,

which makes it a good choice for flues, chimneys, and ducting.

Weathering steel has many

practical advantages over other metals for structures that are exposed to

the weather:

- Very low maintenance:To keep the structure working well, it should only need to be checked and cleaned every so often. Weathering steel is great for bridges and other structures where access is hard or dangerous and where future disruptions need to be kept to a minimum.

- Initial cost benefits:Getting rid of any protective paint system may save more money than the cost of the extra materials. For example, it has been shown that the cost of weathering steel is about 5% less than the cost of other painted steel options in bridges that use a HA Type 2 paint system.

- Whole-life cost benefits:The fact that weathering steel structures don't need much maintenance cuts down on both the direct costs of maintenance operations and the indirect costs of traffic delays or rail possessions.

- Speed of construction:Both shop painting and painting on-site are done away with, which cuts down on overall construction time.

- Appealing look: Mature weathering steel has an attractive appearance that frequently harmonizes well with the surroundings. Its look changes and gets better as it ages.

- Environmental advantages:Future maintenance work won't cause problems with paint's volatile organic compounds (VOCs) or the disposal of blast-cleaning debris.

- Benefits for Safety:Initial painting-related health and safety issues are resolved, and maintenance-related risks are reduced.

- Benefits at high Temperatures:Weathering steels can reduce the amount of steel that rusts at temperatures above 400 degrees Celsius. Even if there is no water around, a patina will form at these temperatures. The exact improvement in performance depends on the heating cycle and the environment. A typical improvement would be an increase of 50 degrees Celsius over the same loss in carbon manganese steels.

Corten Weathering Steel Grades

- Corten A

- Corten B

Corten A Weathering Steel

Corten A is a weather-resistant steel made by mixing copper, chromium, and nickel. Additionally, Corten A has phosphorus added, which makes the substance ideal for gas flue applications and for aesthetically pleasing facias. The material is not advised for use in applications involving heavy loads; in these situations, Corten B or S355J2W should be taken into consideration.

Chemical Composition of Corten A

| C | 0.15 |

|---|---|

| Si | 0.25/0.75 |

| Mn | 0.20/0.50 |

| P | 0.07/0.15 |

| S | 0.030 |

| Al | 0.015/0.06 |

| Cu | 0.25/0.55 |

| Cr | 0.50/1.25 |

| Ni | 0.65 |

Mechanical Properties of Corten A

| Grade | Thickness (mm) Strip Products |

Plate Products | Yield Strength Rel N/mm² Minimum |

Tensile Strength Rm N/mm² Minimum |

Elongation A50 % Minimum |

|---|---|---|---|---|---|

| Corten A | 2-12 | 6-12 | 345 | 485 | 20 |

Corten B Weathering Steel

Corten B

is a type of steel that doesn't rust and is better for large, heavy structures.

When the material is exposed to the elements in the air, it makes its own layer of protection. In

essence, the top layer rusts, which protects the steel underneath. The natural finish usually

doesn't need any maintenance, like painting, which makes the material a much cheaper alternative to

other structural steels.

If the building is always wet, it will need painting and maintenance because a protective layer

won't form. One good example is when the bottom of a building touches the ground or is partly

submerged.

Corten B Chemical Composition

| % | |

|---|---|

| C | 0.19 |

| Si | 0.30/0.65 |

| Mn | 0.80/1.25 |

| P | 0.035 |

| S | 0.030 |

| Al | 0.020/0.06 |

| V | 0.02/0.10 |

| Cu | 0.25/0.40 |

| Cr | 0.40/0.65 |

| Ni | 0.40 |

Corten B Mechanical Properties

| Grade | Thickness (mm) Strip Products |

Plate Products | Yield Strength Rel N/mm² Minimum |

Tensile Strength Rm N/mm² Minimum |

Elongation A50 % Minimum |

|---|---|---|---|---|---|

| Corten B | 2-13 | 6-40 | 345 | 485 | 19 |

Corten B Equivalents Grades

| Corten | EN 10025-5:2004 |

|---|---|

| Corten B | S355J2W |

To learn more about the uses of weathering steel in building and infrastructure projects, please read our article about weathering steel in construction

S355JOWP Weathering Steel

S355J0WP is a weathering structural steel that is also called atmospheric corrosion resistant steel.

The main things that make it an alloy are chromium, nickel, and copper. Phosphorus is also added,

which gives it great self-protecting qualities. As the steel interacts with the elements in the air,

it forms a layer of rust that protects the steel from further damage.

S355J0WP, which is the same grade as Corten A, is a cost-effective and long-lasting structural steel

that can be used in places like steel bridges, stack gas applications, and buildings with steel

sculptures because of the finish.

S355JOWP Chemical Composition

| % | |

|---|---|

| C | 0.16 |

| Si | 0.50 |

| Mn | 0.50/1.50 |

| P | 0.035 |

| S | 0.035 |

| N | 0.009 |

| Cr | 0.40/0.80 |

| Cu | 0.25/0.55 |

Mechanical Properties of S355JOWP

| Grade | Min. Yield Strength ReH MPa | Tensile Strength Rm MPa | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Thickness (mm) | Nominal Thickness (mm) | ||||||||

| <16 | >16 <40 | >40 <63 | >63 <80 | >80 <100 | >100 <150 | >3 | >3 <100 | >100 <150 | |

| S355JOW | 355 | 345 | 335 | 325 | 315 | 295 | 510/680 | 470/630 | 450/600 |

S355JOWP Equivalents Grades

| EN 10025-5:2004 | Corten |

|---|---|

| S355JOW | Corten B |

S355JOW Weathering Steel

S355J0W is also a weathering steel, like S355J0WP, and is the same as Corten B.

When the material is exposed to the elements in the air, it rusts. As it rusts, it builds its own

protective layer, which stops the steel from rusting any more. So, S355J0W, like all weathering

steels, is a great, cost-effective way to protect against the weather without having to paint or

treat the outside.

Most of the time, S355J0WP is used for structures with thinner materials.

S355JOW Chemical Composition

| % | |

|---|---|

| C | 0.16 |

| Si | 0.50 |

| Mn | 0.50/1.50 |

| P | 0.035 |

| S | 0.035 |

| N | 0.009 |

| Cr | 0.40/0.80 |

| Cu | 0.25/0.55 |

Mechanical Properties of S355JOW

| Grade | Min. Yield Strength ReH MPa | Tensile Strength Rm MPa | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Thickness (mm) | Nominal Thickness (mm) | ||||||||

| <16 | >16 <40 | >40 <63 | >63 <80 | >80 <100 | >100 <150 | >3 | >3 <100 | >100 <150 | |

| S355JOW | 355 | 345 | 335 | 325 | 315 | 295 | 510/680 | 470/630 | 450/600 |

S355JOW Equivalents Grades

| EN 10025-5:2004 | Corten |

|---|---|

| S355JOW | Corten B |

S355J2W Weathering Steel

S355J2W is a weather-resistant steel that is meant to be used in load-bearing or heavy structures

due to its higher impact strength. It can also be used in places where the temperature is low.

S355J2W is self-protecting, like all steels that don't rust in bad weather. This is because the

chemical elements in the air cause the steel to rust over time. This layer of rust acts as a barrier

that keeps more oxidation from happening. Steel is cheap to use and can be reused over and over

again. As structural steel, it can be used just as easily to make something look nice as it can to

hold weight.

Benefits of Using S355J2W Steel

- Excellent impact strength

- Ideal for heavy use or in low temperature

- Can be used in–situ without the need for expensive treatment or painting over time

- Popular material with architects for use in steel sculptures and modern structures due to aesthetic appeal

S355J2W Chemical Composition

| % | |

|---|---|

| C | 0.16 |

| Si | 0.50 |

| Mn | 0.50/1.50 |

| P | 0.030 |

| S | 0.030 |

| N | 0.009 |

| Cr | 0.40/0.80 |

| Cu | 0.25/0.55 |

S355J2W Mechanical Properties

| Grade | Min. Yield Strength ReH MPa | Tensile Strength Rm MPa | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Thickness (mm) | Nominal Thickness (mm) | ||||||||

| <16 | >16 <40 | >40 <63 | >63 <80 | >80 <100 | >100 <150 | >3 | >3 <100 | >100 <150 | |

| S355J2W | 355 | 345 | 335 | 325 | 315 | 295 | 510/680 | 470/630 | 450/600 |

S355J2W Equivalent Grades

| EN 10025-5:2004 | Corten |

|---|---|

| S355J2W | Corten B |

FAQ

1Will Weathering Steel Rust?

Rusting away is exactly what Weathering Steel does not do. As a result of its chemical composition, its resistance to air corrosion is greater than that of mild steel. The steel actually rusts on the outside, making what we call a "patina".

2 Is weathered steel expensive?

Weathering steel is a little more expensive than regular structural steel, but the money saved by not having to use paint makes up for the extra cost of the material.

3Are weathering steel and cor-ten the same thing?

The terms "weathering steel" and "cor-ten" are often confused and used interchangeably because they mean basically the same thing. Weathering steel is what people call it in general, while Cor-Ten® is the brand name used by the United States Steel Corporation. As Cor-Ten became more popular, other steel mills started making their own steels that could resist corrosion in the air (AKA weathering steels). In most situations, ASTM created specifications that are the same as Cor-Ten®. The ASTM standards that are the same as cor-ten are A588, A242, A606-4, A847, and A709-50W.

4 Can you paint weathering steel?

Weathering steel doesn't rust, so it can be used in construction and architecture without being painted. However, it CAN be painted. But the surface needs to be cleaned, prepared, and covered with the right materials to look like it has been painted.

5Can weathering steel be welded?

The good news is that it's not too hard to weld weathering steel. Weathering steel can be welded in the same way that low-carbon steels like ASTM A36 and ASTM 572 can.

Alloy Steel - Properties, Types, Uses & Grades

Corten steel commonly known as weathering steel, is highly resistant to rusting and pitting when exposed to the elements. In order to preserve itself, this steel forms an oxide coating.