Everything You Need To Know About Corten Weathering Steel

by AMC

Posted on September 11, 2022 at 12:10 PM

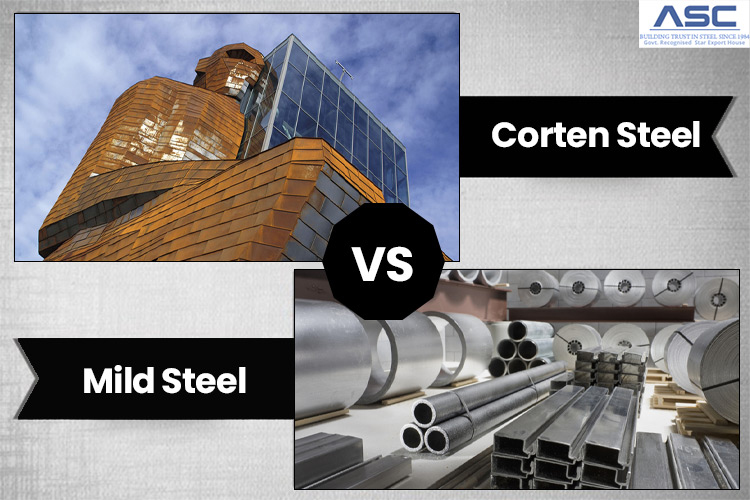

What is Corten Steel?

Coal wagon producers in the United States discovered that certain steel alloys generated a covering

of

rust that, rather than corroding the steel when exposed to the environment, protected it. The

enduring,

earthy, orange-brown patina of these alloys quickly acquired appeal among architects and continues

to

this day. The alloys were developed further to improve their strength and durability.

CorTen, often

known as weathering steel, is a special type of steel that has several unique features that

sculptors

and architects adore. It's unique because it's carefully engineered to build a protective layer of

rust

that protects the steel's deeper layers from corrosion. The advantages are self-evident. However,

there

are more benefits to using Corten

steel in your construction projects.

Interestingly, modern swords are designed with similarly carbon -infused steel. It's known as "high

carbon steel" in the sword industry. It hardens the steel to the point that it can withstand the

abuse

of use that would bend or break lesser steel. Carbon steels are also more prone to rusting on the

surface. The superficial rust is improved for beauty and durability with CorTen.

The Origin Of Corten Steel

In 1933, the United States created and patented the first corten weathering steel.

Steel sold under

the trade name Cor-Ten®, which was so named because of its high tensile strength and low corrosion

rate.

The American Society for Testing and Materials (ASTM) established its product standards. Since the

2000s, the generic term "CorTen" has been used interchangeably with "Cor-Ten®" to refer to

weathering steels. All weathering steel grades are visually and tactilely identical

and have similar

corrosion resistance.

As a result of its durability and low maintenance needs, CorTen quickly gained popularity in the

construction industry after being adapted from its original use in railroad coal wagons. In the

1950s and 1960s, artists and sculptors began using CorTen because of the material's strength and

industrial beauty. One of the most common modern applications for CorTen is in shipping containers.

CorTen A and B

The original CorTen was ASTM A242 which is widely known as Type 1 and Type 2, or CorTen A and CorTen B.

Type 2 (CorTen B) has the addition of vanadium, making it suited to heavy structural applications. It is generally available in 2mm – 40mm thick sheets or plates. In India, Steel Grade S355JOWP is equivalent to CorTen A and S355JOW is equivalent to CorTen B. Another option, S355J2W, which is also equivalent to CorTen B, is more economical but also fully recyclable.

How Does Corten Steel Gain Its Patina?

Corten weathering steel is a combination of steel and alloys that vary depending on the grade. Its dull, dark grey appearance may indicate that the wrong product was delivered before contact with the weather, but it will develop a patina that is unique to each piece over time. This natural palette is influenced by humidity, warmth, and airborne contaminants, with oxidation occurring more quickly in more exposed areas and if water lingers on the surface rather than draining away.

Manufacturing and Weathering

In order to create corten weathering steel, the metal is heated to extremely high temperatures and

then rolled between two sets of rollers. Mill scale, a byproduct of iron processing, rises to the

top during this procedure. In the beginning phases of weathering, this causes rust to run off and

staining.

After the initial iron waste layer rusts away, the material's surface is durable and resistant to

shedding and staining. The process can be sped up by using an acid treatment called "pickling" to

remove the mill scale from the raw material before it is shipped.

Why is Corten Steel So Popular?

The strength, durability, practicality, and aesthetic appeal of Corten weathering steel contribute

to its popularity. Corten can sustain stronger forces before buckling or breaking, with a tensile

strength of 68-78 KSI compared to 45-64 KSI for galvanized steel sheets.

Corten is protected against corrosion in most settings by a naturally occurring protective

oxidized coating. Corten doesn't need to be painted or treated regularly. If the oxidized layer is

scraped, new steel is exposed which oxidizes quickly and blends in with the remainder of the

surface. The raw, natural beauty of its patina, which merges naturally with other natural materials

such as wood and stone and gives a striking contrast to the rich greenery of flora, must be the main

reason for its popularity in landscape architecture.

Why to Go for Corten Steel?

Because conjoined joints will fuse via surface rust, this special steel allows for particular design

styles. This fact makes the steel popular among sculptors, who profit from the capacity to create

unique new shapes. However, the fusing quality of Corten can benefit even simple constructions. If

you built a steel structure out of this material, it would become one solid piece from end to end,

ceiling to floor, within a year or two, making it highly stiff and durable.

The "Spomeniks," massive sculptures dispersed throughout the vast landscapes of Germany and

Yugoslavia, memorialize significant World War II engagements. These structures are eerie in their

size and isolation. Many of them have become permanent behemoths displaying the horrors of war for

countless generations to see, thanks to the use of Corten weathering steel.

Similarly, several civic engineers have leveraged CorTen's capabilities to design walkways,

barriers, and floating canals that would not be conceivable with other materials. These structures,

like the monuments of the European hillside, benefit from the metal's naturalistic red rock-like

patina.

Although Corten steel is resistant to corrosion, it is not rust-proof. The temperature and

environmental elements play a big role in how long Corten steel lasts and how soon the

protective layer of rust forms. Within six months of atmospheric exposure, Corten steel will patina

or rust. To develop and oxidize, most weathering steel types require wet/dry weather cycles. Corten

steel can survive anywhere from a few decades to over 100 years because of the protective rust that

provides corrosion resistance. Saltwater or a mixture of salt solutions mixed with vinegar and

peroxide can speed up the rusting process on Corten.

What Are the Benefits of Corten Weathering Steel?

Although Corten weathering steel is mostly utilized for aesthetic purposes, it also has the following advantages:.

Uses of Corten Steel

Overall Appearance

The ultimate appearance of Corten steel is determined by the conditions under which it is installed.

For instance, its appearance will vary depending on whether you're on the ocean, inland, or in the

shade. The charm of Corten weathering steel lies in its inherent finish irregularities.

However, design and installation must take into account the fact that water pooling and puddling may

diminish the material's beauty and lifespan. The color of steel will change to a deeper shade as it

matures.

We Are Here!

Corten and weathering steel are essentially the same material that offers excellent strength and

corrosion resistance and are often used interchangeably. Corten steel is perfect for architectural

and landscaping projects in the outdoors. Corten steel, which is popular for its aesthetics,

develops a patina (rust) that protects it against corrosion and the weather. The flexibility to

employ corten weathering steel in a variety of applications without the requirement for initial

painting and maintenance is one of its most appealing features.

At Amardeep Steel Center, we’ve got you covered. We provide products in both the forms- untreated

steel and finished cor-ten. Amardeep Steel Centre is a globally famous manufacturer and supplier of

Cortne Seel Plates & Sheet, Cortne Steel Pipe & Tube & other Grades like ASTM A423, ASTM A847, ASTM

A588 GR A , ASTM 588 GR B. We have overcome all the challenges and lived up to our slogan of

Building Trust In Steel Since 1984.

What is Weathering Steel? - Its Benefits, Grades & Chemical Composition

Weathering steel is a family of low-carbon steels that have other elements mixed in with the carbon and iron. Because of these alloying elements.