Alloy Steel vs. Stainless Steel

by AMC

Posted on February 14, 2022 at 04:52 PM

.jpg)

Learn more about the differences between alloy steel and stainless steel and their properties.

Alloy steel is a type of steel that is made by combining two or more different metals or elements to improve its properties. The specific combination of metals and their ratio can vary depending on the intended application and desired properties of the steel. Some common elements used in the creation of alloy steel include nickel, chromium, molybdenum, and manganese. These elements are added to improve the steel's strength, hardness, corrosion resistance, and other properties.

Stainless steel is an alloy of steel that contains at least 10.5% chromium by weight. The chromium provides the steel with a passive oxide layer that protects the material from corrosion and staining. Other elements that may be added to stainless steel to improve its properties include nickel, molybdenum, and nitrogen.

The exact composition of stainless steel can vary depending on the type and the intended application. For example, austenitic stainless steel, which is the most commonly used type of stainless steel, contains high amounts of nickel and chromium. Martensitic stainless steel, on the other hand, contains less nickel and more carbon and is known for its high strength and hardness.

What is Alloy Steel?

Alloy steel is a catch-all term for steel that has one or more alloying elements added to it. Iron and a small amount of carbon are the two main components of steel. The most common extra element added to steel is chromium, which makes it resistant to corrosion. Manganese, molybdenum, nickel, titanium, tungsten, and vanadium are some other elements that can be added to steel to make it stronger. The properties of alloy steel depend on the elements that are added to it. For example, chromium makes steel harder, tougher, and more resistant to wear, while manganese makes it easier to shape, harder, and more resistant to wear.

What is Stainless Steel?

Stainless steel is a type of steel that has been mixed with other metals. It has at least 10.5% chromium, which makes it very resistant to rust. Because it has chromium added to it, it can be used for a wide range of things, from cooking tools to medical equipment. It is a popular choice for both consumers and businesses because of the unique things it can do. It is significant to remember that there are various grades of stainless steel, each with a unique set of characteristics.

What Are the Properties of Alloy Steel?

Table 1 highlights the properties of Alloy Steel:

| Physical Properties | Chemical Properties |

|---|---|

|

Physical Properties

High strength-to-weight ratio. |

Chemical Properties

Contains high levels of chromium, molybdenum, and/or other alloying elements. |

|

Physical Properties

Good corrosion resistance |

Chemical Properties

The higher levels of alloying elements often allow alloys to be heat-treated to a wide range of hardness levels. |

|

Physical Properties

High strength and durability |

Chemical Properties

|

|

Physical Properties

Resistance to wear |

Chemical Properties

|

|

Physical Properties

Hardness at high temperatures |

Chemical Properties

|

Read more about the - Properties of Alloy Steel

What Are the Properties of Stainless Steel?

Table 2 highlights the properties of stainless steel:

| Physical Properties | Chemical Properties |

|---|---|

|

Physical Properties

Resistant to corrosion and staining |

Chemical Properties

Resistant to bases, acids, and also organic compounds |

|

Physical Properties

Durable |

Chemical Properties

Composed of iron, chromium, and carbon. Some varieties may include manganese, silicon, nickel, or other elements |

|

Physical Properties

Easy to clean and maintain |

Chemical Properties

|

|

Physical Properties

Non-magnetic |

Chemical Properties

|

|

Physical Properties

High resistance to heat |

Chemical Properties

|

|

Physical Properties

Electrically conductive |

Chemical Properties

|

What Are the Types of Alloy Steel?

There are many different types of alloy steel, each with unique properties and characteristics. Most common types of alloy steel include:

- High-Strength Low-Alloy Steel (HSLA): HSLA steel is designed for use in high-stress applications and is known for its high strength and low weight.

- Tool Steel: Tool steel is an alloy steel that is used in cutting and forming tools. It is known for its high hardness and wear resistance.

- Maraging Steel: Maraging steel is a type of alloy steel that is known for its high strength and toughness. It is often used in applications that require high stress resistance, such as aerospace components and medical devices.

- Nickel Steel: Nickel steel is an alloy of steel that contains a high amount of nickel. It is known for its high strength, toughness, and resistance to corrosion.

- Manganese Steel: Manganese steel is an alloy of steel that contains a high amount of manganese. It is known for its high hardness and wear resistance.

- Carbon Steel: Carbon steel is a type of alloy steel that contains a high amount of carbon. It is known for its high strength and low cost.

- Chromium Steel: Chromium steel is an alloy of steel that contains a high amount of chromium. It is known for its high hardness and wear resistance.

These are just a few examples of t he many different types of alloy steel. The specific type of alloy steel used in a particular application will depend on the desired properties and the intended use of the material.

What Are the Types of Stainless Steel?

There are several different types of stainless steel, each with unique properties and characteristics:

- Austenitic: This is the most common type of stainless steel and is characterized by its high nickel content. It is known for its excellent corrosion resistance, formability, and weldability.

- Ferritic: Ferritic stainless steel contains high levels of chromium but low levels of nickel. It is known for its good corrosion resistance, but is typically less durable and less ductile than austenitic stainless steel.

- Martensitic: Martensitic stainless steel is known for its high strength and hardness. It is often used in applications that require high strength, such as cutting tools and valve components.

- Duplex: Duplex stainless steel is a type of stainless steel that combines the properties of austenitic and ferritic stainless steels. It is known for its high strength, corrosion resistance, and good ductility.

- Precipitation Hardening: This type of stainless steel is known for its high strength and hardness, which can be improved through heat treatment. It is often used in applications that require high strength and good corrosion resistance, such as aerospace components.

These are the main types of stainless steel, but there are also many subcategories and variations within each type. The specific type of stainless steel used in a particular application will depend on the desired properties and the intended use of the material.

What Are the Advantages of Alloy Steel Compared to Stainless Steel?

Alloy steel and stainless steel are both highly versatile materials that are used in a wide range of applications. However, each type of steel has its own unique advantages and disadvantages:

Advantages of Alloy Steel:

- Strength: Alloy steel has a higher strength-to-weight ratio than many other types of steel, making it an excellent choice for applications that require high strength.

- Toughness: Alloy steel is often more impact-resistant than stainless steel, making it a good choice for applications that require good toughness.

- Cost: Alloy steel is typically less expensive than stainless steel, making it an economical choice for many applications.

- Weldability: Alloy steel is typically easier to weld than stainless steel, making it a good choice for applications that require welding.

Advantages of Stainless Steel:

- Corrosion Resistance: The high chromium content of stainless steel provides excellent corrosion resistance, making it a good choice for applications that are exposed to corrosive environments.

- Aesthetic Appeal: Stainless steel has a bright, attractive appearance, making it an excellent choice for applications that require a good visual appearance.

- Longevity: Stainless steel is known for its long service life, making it a good choice for applications that require a long lifespan.

- Non-Reactivity: Stainless steel is non-reactive, meaning that it does not corrode, rust, or stain when it comes into contact with other materials.

Each type of steel has its own unique advantages, and the best choice for a particular application will depend on the specific requirements and intended use of the material. In some cases, alloy steel and stainless steel may be used in combination to take advantage of the strengths of each material.

What Are the Disadvantages of Alloy Steel Compared to Stainless Steel?

Disadvantages of Alloy Steel:

- Corrosion Resistance: Alloy steel does not have the same level of corrosion resistance as stainless steel, making it more susceptible to rust and corrosion in certain environments.

- Weldability: While alloy steel is typically easier to weld than stainless steel, it is also more prone to cracking and warping during the welding process.

- Toughness: While alloy steel is known for its high strength, it may not be as tough as stainless steel in certain applications.

Disadvantages of Stainless Steel:

- Cost: Stainless steel is typically more expensive than alloy steel, making it a less economical choice for some applications.

- Formability: Stainless steel is typically less formable than alloy steel, making it a less suitable choice for applications that require a high degree of formability.

- Magnetism: Some types of stainless steel are magnetic, which can cause issues in certain applications, such as electronic components.

The choice between alloy steel and stainless steel will depend on the specific requirements of the application and the intended use of the material. Factors such as cost, strength, toughness, and corrosion resistance will all play a role in the decision-making process.

What Are the Comparisons Between Alloy Steel and Stainless Steel?

Table 3 compares alloy steel vs. stainless steel in terms of thermal conductivity, tensile strength, and application:

| Alloy Steel | Stainless Steel | |

|---|---|---|

|

Alloy Steel

Thermal Conductivity |

Stainless Steel

Has a thermal conductivity of about 45 W/(mK). |

Has a thermal conductivity of 15 W/(mK). |

|

Alloy Steel

Tensile Strength |

Stainless Steel

More durable and has a tensile strength of up to 960 Mpa |

Less durable and has a tensile strength of about 621 Mpa |

|

Alloy Steel

Application |

Stainless Steel

Often used in construction and manufacturing |

Commonly used in the food and beverage industry |

What Materials Can Replace Alloy Steel and Stainless Steel?

It may be necessary to find alternative materials that offer similar properties. Some of the materials that can replace alloy steel and stainless steel include:

Materials that can replace Alloy Steel:

- Aluminum Alloys: Lightweight aluminum alloys can be used as a substitute for alloy steel in certain applications where weight reduction is a priority.

- Carbon Steel: Low-carbon steel can be used as a substitute for alloy steel in applications that do not require high strength.

- Titanium Alloys: Titanium alloys can be used as a substitute for alloy steel in high-performance applications, such as aerospace and military applications.

Materials that can replace Stainless Steel:

- Aluminum Alloys: Aluminum alloys can be used as a substitute for stainless steel in certain applications, such as kitchenware and cookware.

- Brass: Brass can be used as a substitute for stainless steel in certain applications, such as decorative hardware.

- Titanium Alloys: Titanium alloys can be used as a substitute for stainless steel in certain applications, such as aerospace and biomedical implants.

The choice of a replacement material will depend on the specific requirements of the application, including factors such as strength, toughness, cost, and corrosion resistance. It is important to carefully evaluate the properties of each material and how they will perform in the intended application before making a final decision.

What are some of the things that alloy steel and stainless steel have in common?

Despite their differences, they do share some similarities:

- Strength: Both alloy steel and stainless steel are known for their high strength, making them suitable for use in demanding applications.

- Durability: Both materials are highly durable and long-lasting, making them ideal for use in applications that require longevity.

- Versatility: Both alloy steel and stainless steel can be used in a wide range of applications, including construction, engineering, and manufacturing.

- Recyclability: Both alloy steel and stainless steel are recyclable, making them an environmentally friendly choice in many applications.

- Cost-effective: Both materials are cost-effective, making them a popular choice for many applications where cost is a consideration.

Summary

This article talked about alloy steel and stainless steel. It described what they are and what they are used for. Contact a Amardeep official to find out more about alloy steel and stainless steel.

For all of your prototyping and production needs, Amardeep offers a wide range of manufacturing services and other services that add value. Visit our website to find out more or to get a free quote with no obligation.

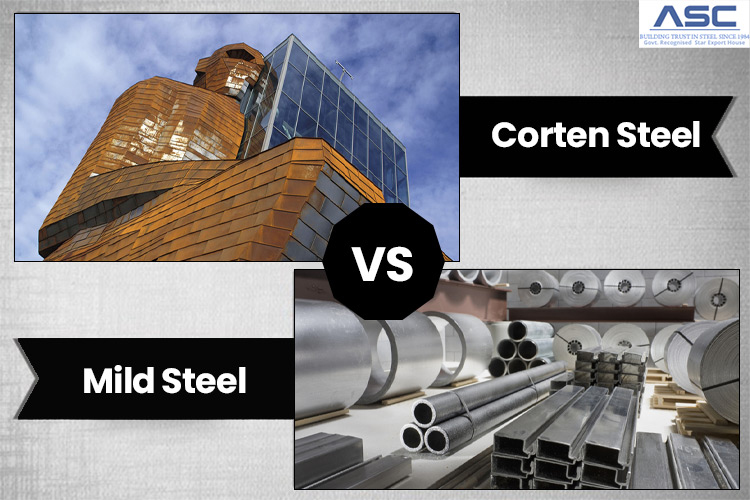

Difference Between Corten Steel and Mild Steel

Mild steel, also known as carbon steel, is the most prevalent type of steel today. Mild steel is less expensive and, once sealed, will keep a naturally rusty appearance.

What is Weathering Steel?

Weathering steel is a family of low-carbon steels that have other elements mixed in with the carbon and iron. Because of these alloying elements.

Benefits And Rusting Capabilities Of Corten Steel

Corten steel commonly known as weathering steel, is highly resistant to rusting and pitting when exposed to the elements.